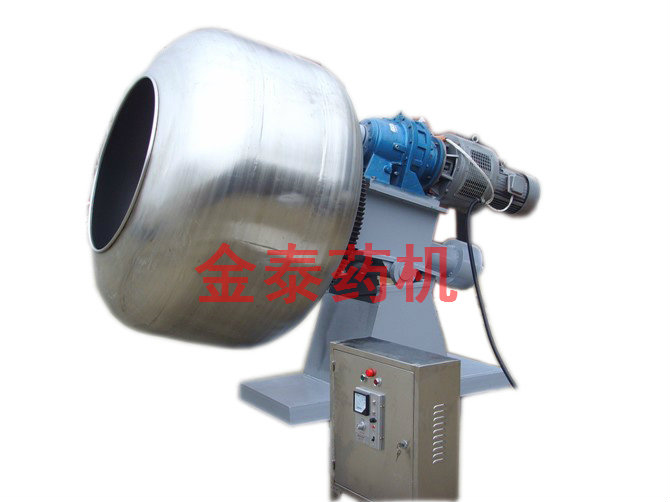

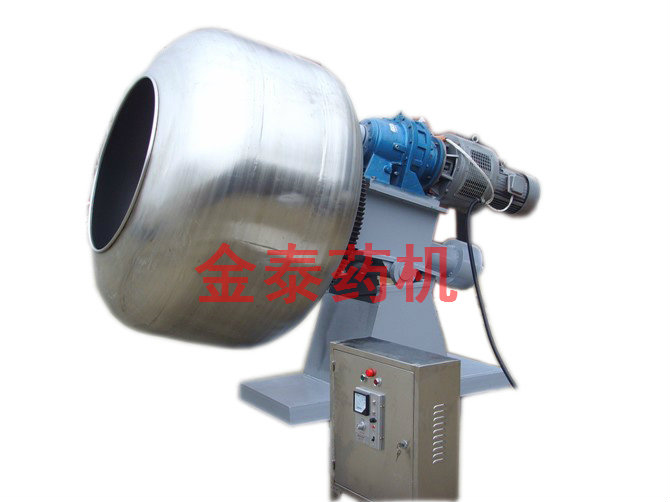

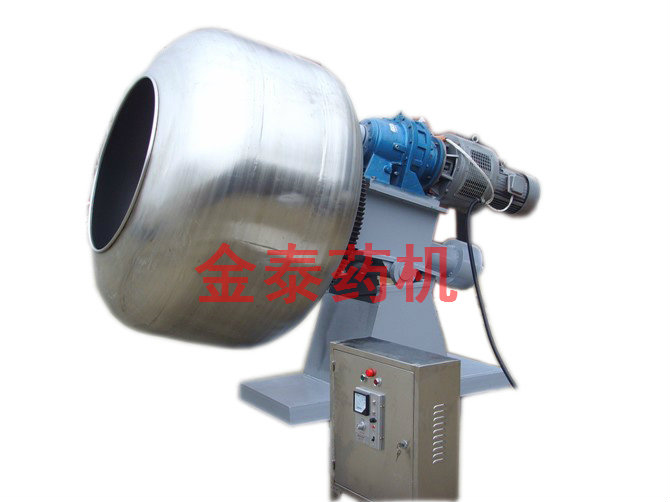

Special coating machine

Category:Coating machine

- Hits:

- Date:2014/09/08

Details

A, coating machine for different purposes

A, coating machine for different purposes

Alien icing machine is mainly used in pharmaceutical industry of pressing tablets, pills and particle coating.Can also be used in the food industry candy mechanism or coating.Also can make the plasticity material rolling into a pill.Coating after polishing sugar pill with shining surface, can prevent oxidation, be affected with damp be affected with damp or volatile, but also cover the discomfort of taste, to facilitate recognition and ease in human gastrointestinal drug dissolution.

Second, the different coating machine main technical parameters

Model parameters BY - 1500

Pot body diameter (1500 mm)

Production capacity (kg/day), 300-400

Dip a (adjustable) 15 ° to 45 °

Pot body rotation speed (r/min) 33

The main motor 7.5 KW Y90L - 4

1400 r/min

Lifting motor 1.1 KW

Overall dimensions (length * width * height) 2200 x1500x1800

Machine weight (850 kg)

Three, different icing machine working principle

Pot body clockwise, the pot chips by several times after spray syrup and mix slurry, make the syrup mix evenly coated on the chip, and make it in the pot.

The machine is in reasonable shape, stable linear velocity makes the tablet in the pot to form the best logistics flow curve, not only can satisfy the requirement of the package of icing process.Still can make plasticity material roll into pellets, and surface polishing.

Main motor through the cycloid pin wheel reducer, make a pot body get reasonable rotation, the pot body smooth operation.

Four, the structure of the different coating machine

This machine is mainly composed of the base part, work, and Angle adjusting part

1. The base part of chassis, host, brackets, Angle brackets and Angle adjusting machine, universal regulator guide rail and the limit switch, etc.

The host on the brackets is equipped with two bearing part connected with work

2. Working part consists of pot body, cycloidal pinwheel reducer main motor and speed reducer bearing installation, the pot body and main motor and speed reducer through a flat key and bolt connection between installed on the bearing, bearing lower welding before have a shaft connected to the host on bearing brackets.After the bottom has a guide rail

3. Angle adjustment part by the Angle adjustment screw, speed reducer and motor, motor through a belt rotation drive reducer to screw up, down, the upper screw rolling device, installed in the main reduction stand back, universal controller for main speed reducer support up and down, adjust the pan tilt Angle.Adjust the Angle by the installation on the base part of the limit switch among 15 ° to 45 ° limit control Angle can be arbitrary regulation.

Five, the coating machine for different use and maintenance

Use:

1, whether to add lubricating oil must be checked before starting the reducer, and to the oil line, machine parts whether fasteners loose, wipe the pan body.

2, sugar pot Angle and relevant devices and object exchange performance, dip Angle of 30 ° when production efficiency and quality are good

3, the host USES the star step-down start triangle runs automatically.Star should start in 5 seconds automatically with trigonometric function, such as too long should be clockwise to adjust time relay, make star start between 5-10 seconds, avoid damage to the motor.When confirm start, automatic, transform operating normally put into production.Idle machine for 2 minutes, no abnormal phenomenon can be put into work.

Maintenance:

1, should be replaced periodically reducer lubricating oil, and add a rolling bearing grease, lubricating oil can be replaced every six months.

2, if machine for a long time without should be clean, cover to cover.

3, repair electrical appliances should be superior cover plate, ensure safe use.

4, the machine must be grounded.

A, coating machine for different purposes

A, coating machine for different purposesAlien icing machine is mainly used in pharmaceutical industry of pressing tablets, pills and particle coating.Can also be used in the food industry candy mechanism or coating.Also can make the plasticity material rolling into a pill.Coating after polishing sugar pill with shining surface, can prevent oxidation, be affected with damp be affected with damp or volatile, but also cover the discomfort of taste, to facilitate recognition and ease in human gastrointestinal drug dissolution.

Second, the different coating machine main technical parameters

Model parameters BY - 1500

Pot body diameter (1500 mm)

Production capacity (kg/day), 300-400

Dip a (adjustable) 15 ° to 45 °

Pot body rotation speed (r/min) 33

The main motor 7.5 KW Y90L - 4

1400 r/min

Lifting motor 1.1 KW

Overall dimensions (length * width * height) 2200 x1500x1800

Machine weight (850 kg)

Three, different icing machine working principle

Pot body clockwise, the pot chips by several times after spray syrup and mix slurry, make the syrup mix evenly coated on the chip, and make it in the pot.

The machine is in reasonable shape, stable linear velocity makes the tablet in the pot to form the best logistics flow curve, not only can satisfy the requirement of the package of icing process.Still can make plasticity material roll into pellets, and surface polishing.

Main motor through the cycloid pin wheel reducer, make a pot body get reasonable rotation, the pot body smooth operation.

Four, the structure of the different coating machine

This machine is mainly composed of the base part, work, and Angle adjusting part

1. The base part of chassis, host, brackets, Angle brackets and Angle adjusting machine, universal regulator guide rail and the limit switch, etc.

The host on the brackets is equipped with two bearing part connected with work

2. Working part consists of pot body, cycloidal pinwheel reducer main motor and speed reducer bearing installation, the pot body and main motor and speed reducer through a flat key and bolt connection between installed on the bearing, bearing lower welding before have a shaft connected to the host on bearing brackets.After the bottom has a guide rail

3. Angle adjustment part by the Angle adjustment screw, speed reducer and motor, motor through a belt rotation drive reducer to screw up, down, the upper screw rolling device, installed in the main reduction stand back, universal controller for main speed reducer support up and down, adjust the pan tilt Angle.Adjust the Angle by the installation on the base part of the limit switch among 15 ° to 45 ° limit control Angle can be arbitrary regulation.

Five, the coating machine for different use and maintenance

Use:

1, whether to add lubricating oil must be checked before starting the reducer, and to the oil line, machine parts whether fasteners loose, wipe the pan body.

2, sugar pot Angle and relevant devices and object exchange performance, dip Angle of 30 ° when production efficiency and quality are good

3, the host USES the star step-down start triangle runs automatically.Star should start in 5 seconds automatically with trigonometric function, such as too long should be clockwise to adjust time relay, make star start between 5-10 seconds, avoid damage to the motor.When confirm start, automatic, transform operating normally put into production.Idle machine for 2 minutes, no abnormal phenomenon can be put into work.

Maintenance:

1, should be replaced periodically reducer lubricating oil, and add a rolling bearing grease, lubricating oil can be replaced every six months.

2, if machine for a long time without should be clean, cover to cover.

3, repair electrical appliances should be superior cover plate, ensure safe use.

4, the machine must be grounded.